Products

- HOME

- Industrial processing equipment

- Punching

- Linear type Multi Product Punching Machine Selectable set of punch and die+Punch unit

Punching

Industrial processing equipmentトップLinear type Multi Product Punching Machine Selectable set of punch and die+Punch unit

MPRO-□in □PL series

- Ceramic Green Sheet

- MPRO-SELECTin150PL / MPRO-SELECTin200PL

- Speed-up MPRO Super-high-speed X and Y axes is installed.

- Die set unit: Max.900 hole/min × Punch number in metal mold Compared with our conventional model 1.5 times

Punching unit: Max.1500 hole/min (with PUM-25L) 2.5times faster than conventional models

Characteristics

- Punching dies with the higest speed in the world

- Flexible productivity

- Product punching machine can versatilely meet any scale of producton from proto-type work to mass-production.

- Decrease of initial running cost

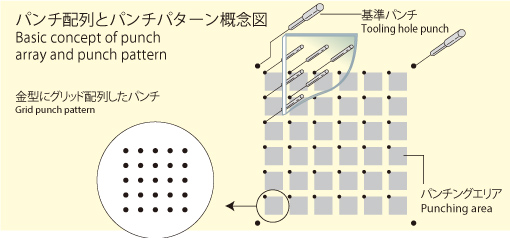

- Grid array that can freely conform to punch pattern Combination of die set unit and punching unit realizes flexible punching arrangements and decrease of die cost.

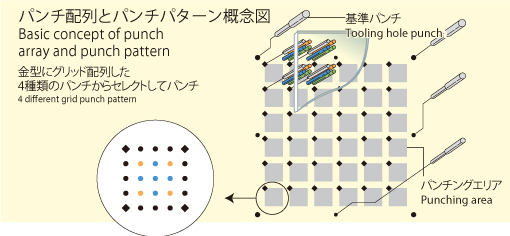

- Basic concept of punch array and punch pattern

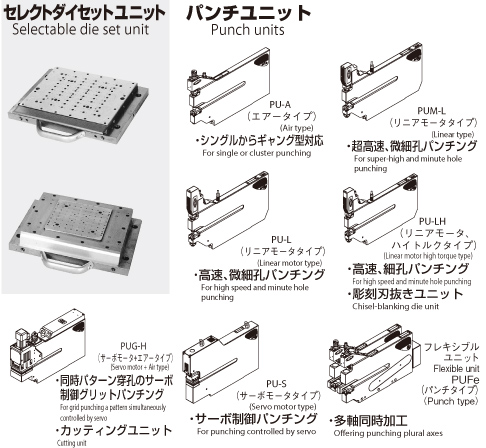

- Selectable die set unit

- Selectable die set unit out of various grid arrays. 4 different size of punch is efficiently selectable.(Square punch available)

Standard Specifications

| Model name | MPRO-SELECTin150PL | MPRO-SELECTin200PL | ||

|---|---|---|---|---|

| Work | Material | Ceramic Green Sheet | ||

| Form | Sheet | |||

| Thickness | Max.0.5mm | |||

| Sheet size | Max.□175mm (RC:□200mm) |

Max.□225mm (RC:□250mm) |

||

| Punching area | Max.□150mm | Max.□200mm | ||

| Attachment (How to attach) |

Supply : Sheet : Standard Work holder, Vacuum frame Roll : Vacuum frame |

|||

| Punch | Die set unit | Layout in Max.□200mm 4 different diameters' punching holes are settable. |

||

| PU unit | 8axes(PU-25 In-serve number) An unit selected by you | |||

| Capability | Punching accuracy | ±10μm(Between 2 points in 1" punched on UHT's test film) | ||

| Punching speed | Diesetunit | Die set unit : Max. 900 holes/min + Tooling hole punches (With 1.0mm pitch) |

||

| PUunit | By PUM-25L : Max.1500 hole/min By P U - 2 5 L : Max.1000 hole/min By P U - 2 5 A : Max. 600 hole/min (NC punch with 1mm pitch in Y direction on and standard V/F work holder) |

|||

| Control function | Control | Controller : UHT made MJUC controller | ||

| Operation | 6.5" color LCD touch panel | |||

| Punch data | Software on PC (independent of the main body) | |||

| Data | 1file(30000 positions) | |||

| Network | Data transfer from P/C to machine through | |||

| Dust collector | Die set unit | External dust collector | ||

| Punching unit | By three reams SJC dust collect method | |||

| Power | 3φ AC200V±10% 3kVA | |||

| Air | 0.4MPa~0.7MPa | |||

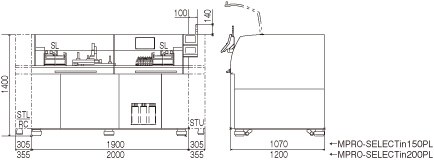

| Machine size(Body) | W1900×D1070×H1400mm | W2000×D1200×H1400mm by slide loader:SL |

||

| Machine mass | Approx. 2400kg | |||

| Working condition | Temperature | 10~35℃(22±2℃ recommended) | ||

| Humidity | 40~60%(Non-dewing) | |||

Options

- Punch setter

- Metal mold(Punch, Die)

- Power box

- Selectable die set unit

- Data conversion software from CAD

- PC

- Punch units

- Punch break detecting software

- Booster tank

Outline Drawing

Industrial processing equipment Product lineup

Support

Contact Us

- Inquiries about products

Request catalog here

- Reception time:9:00~18:00(Weekday)