Products

Pilot hole punching machine

Industrial processing equipmentトップPZ-DESK・□ series

- PZ-DESK / PZ-DESKg

- PZ-DESK・B / PZ-DESK・Bg

- PZ-DESK・B2 / PZ-DESL・B2g

- PZ-DESK・H / PZ-DESK・Hg

- This series has been discontinued.

The successor model will be PZ-Di/PZ-Dh. - PZ-Di/PZ-Dh

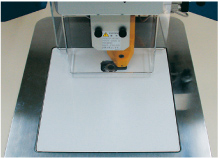

- Stable punching accuracy achieved by the automatic image processing positioning.

- The image processing by gray scale, binary-coded measurement, and vacuum offset table corresponds to various materials and marks.

- Set and controlled by the remote controller.

- The operation part can be separated from the machine body. And the machine is controlled by the remote-controller to prevent erroneous operations and secure the operator's safety.

- Simple and compact appearance with a brainchild of ergonomic designing.

- Its simple and compact design ensures a high operation efficiency.

- Uses

- Through-hole drilling for phenol resin, glass epoxy resin, etc.

Characteristics

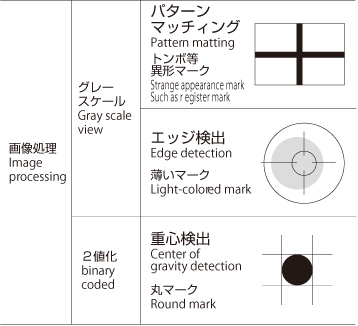

- Image processing

- Suitable image processing for mark can be selected.

- LCD monitor

- The bright and wide screen can display target mark and letters clearly and it's improving the operation efficiency. There is no concern about the influence of electromagnetic waves to the operator. Furthermore, this monitor can be replaced easily.

- Remote control

- The operation part can be separated from the machine body. And the machine is controlled by the remote-controller to prevent erroneous operations and secure the operator's safety.

- Menu screens

Standard Specifications

| Model | PZ-DESK PZ-DESKg |

PZ-DESK B PZ-DESK Bg |

PZ-DESK B2 PZ-DESK B2g |

PZ-DESK H PZ-DESK Hg |

||

|---|---|---|---|---|---|---|

| Work | Material | Flexible substrates/Name plate | Glass epoxy/Flexible multilayer substrates/Name plate | Metallic substrates/Name plate/Flexible substrates | ||

| Size | Max.610×510mm | |||||

| Work thickness | Max.1mm | Max.1.6mm | ||||

| Die size | Punched hole diameter | φ0.6~3.0mm(OP.φ3.9mm) | φ0.6~6.0mm(OP.φ6.49mm) | φ1.0~6.0mm(OP.φ6.49mm) | ||

| Capability | Punching power | 800N | 1100N | 2000N | 8600N | |

| Punching accuracy | ±20μm | |||||

| Punching speed | Max.1.5sec | Max.2.2sec | ||||

| From pressing foot pedal to completion of punching Under UHT's processing conditions |

||||||

| Image processing | Image processing | Centering by binary-coded threshold level 256 levels | ||||

| Pattern matching and edge detection by gray scale /centering by binary-coded threshold level 256 levels | ||||||

| Display | 5.5inch TFT LCD | |||||

| Mark size | φ0.6~3.0mm | φ1.0~6.0mm | ||||

| Range of view | Standard view5×4mm Digitized view4.5×3.5mm | Standard view12×9mm Digitized view10×8mm | ||||

| Light | LED lamp from upper side (3colors), LED lamp from Lower side | LED lamp from upper side (3colors) | ||||

| Control function | Operation | Operated by the remote controller | ||||

| Table | Movable for correcting a vacuum position | |||||

| Power source | Single phase AC85~265V 500VA | |||||

| Air consumption | Vacuum | ON | 4.4ℓ /hole(cycle) | 6.6ℓ /hole(cycle) | 6.3ℓ /hole(cycle) | |

| OFF | 1.0ℓ /hole(cycle) | 1.5ℓ /hole(cycle) | 1.5ℓ /hole(cycle) | |||

| Air source | 0.5MPa | |||||

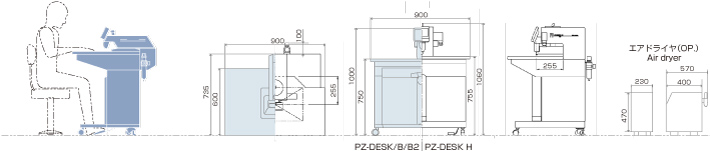

| Machine size | W900×D735×H1000mm | W900×D735×H1060mm | ||||

| Machine weight | Approx.90kg | Approx.100kg | Approx.170kg | |||

| Working condition | Temperature | 10~35℃(22±2℃ recommended) | ||||

| Humidity | 40~60%(Non-dewing) | |||||

| Accessories | Remote Controller (AAA size battery),Hexagonal wrench set (3 types), Punch・Die Replace tool, Punch・Die・Stripper | Spring (for stripper),Pinspana, Vacuum type sheet, Air dryer | ||||

| Option | Dies (punches, dies and strippers), dust taking air blow, and legs for standing work (table height: 920mm) | |||||

Options

| Work Material | Flexible substrates/Name Plate Glass epoxy/Flexible multilayer substrates/Name plate:B2g/B2Type |

Metallic substrates/Name Plate/Flexible substrates | |||||

|---|---|---|---|---|---|---|---|

| Thin | Thin~Middle thick | Thick | |||||

| Punching power & Punche hole diameter | 800N φ0.6~3.0mm |

1100N 2000N:B2g/B2タイプ(Type) φ0.6~6.0mm(OP.φ6.49mm) |

8600N φ1.0~6.0mm(OP.φ6.49mm) |

||||

| Image processing | Gray scale view binary coded |

|

|||||

| binary coded | |||||||

|

|

|

|||||

| Light | Upper | 〇 | 〇 | 〇 | |||

| Lower | 〇 | 〇 | |||||

LED lamp from upper side (3colors) |

From underneath:Built-in lamp in updown die system |

LED lamp from upper side (3colors) |

|||||

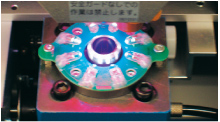

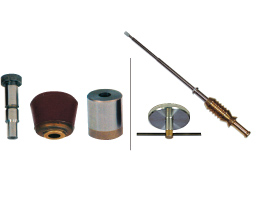

| Swing punch mechanism | This swing punch mechanism, mounted with a CCD camera on the punch shaft, has achieved high precision punching. | ||||||

|

|

|

|||||

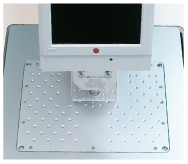

| X-Ytable (vacuum type) |

This X-Y table can precisely follow the image data coming from the CCD camera with a high precision of 4μm/pulse. Only by sliding the work into the view field of the LCD monitor, matching the target marks setting with the work, and pressing the foot pedal, the work is automatically vacuumed and positioned for punching. This easy operation has solved a problem of quality contribution caused by the difference of operator's skill.

|

|

|||||

| Punch and die replacement | One-touch die replacement. The punch replacement is also easy. After replacement, the only thing to do is the fine adjustment of the die. Long life of punch and die and it ensures a stable precision punching. | ||||||

| Punch Stripper Die | Replace tool |  |

|

|

|||

Outline Drawing

Industrial processing equipment Product lineup

Support

Contact Us

- Inquiries about products

Request catalog here

- Reception time:9:00~18:00(Weekday)