Products

- HOME

- Industrial processing equipment

- Cutting

- High-speed,High-accuracy cutting machine

Cutting

Industrial processing equipmentトップHigh-speed,High-accuracy cutting machine

G-CUT J8 series

- Laminated ceramic sheets

- G-CUT J8 / JW8 Type M

- G-CUT J8 / JW8 Type L

- G-CUT J8 Type A

- Cutting speed of 540 cuts/min (Type M)

- Cutting speed of 300 cuts/min using a vision system (Type A)

- Desired system configuration is available for your purpose by choosing from a wide variety of options

- High-cost performance machine

Characteristics

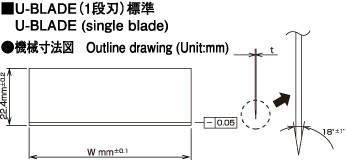

- Three types available depending on the production purpose

- Type M is a manual feeding machine for low-volume production, Type L is equipped with an

automated loading system for volume production, and Type A for processing MLCCs - Optional functions

- Available options including double-blade cutting, camera, image processing, cleaner, heating, and pre-alignment

- Multi-language-ready touch panel

- Clean and eco-friendly dry cutting

Standard Specifications

| Model | G-CUT J8/JW8 | ||||||

|---|---|---|---|---|---|---|---|

| Type | Type M (Basic) |

Type M (High accuracy) |

TypeA (High accuracy, High Speed) |

||||

| - | Image processing using camera | ||||||

| Main Unit | Work | Material | Laminated ceramic green sheet | ||||

| Thickness | Max.5.0mm | ||||||

| Size | Min.□50mm〜Max.□225mm | Min□35mm~Max□225mm | |||||

| Capability | Cutting accuracy | NC | ±10μm | ±5μm | |||

| Image prosessing | − | ±20μm | ±15μm | ±7μm | |||

| Cutting speed | NC | 540 cuts/min (1-mm pitch feed in Y direction at 2-mm Z-axis height) |

450 cuts/min (1-mm pitch feed in Y direction at 2-mm Z-axis height) |

480 cuts/min (1-mm pitch feed in Y direction at 2-mm Z-axis height) |

|||

| Image prosessing | − | 150 cuts/min(2-mm pitch feed in Y direction at 20-mm Z-axis height) | 300 cuts/min(1-mm pitch feed in Y direction at 2-mm Z-axis height) | ||||

| Cutting power | 3600 N (maximum instantaneous power: 12600 N) | ||||||

| Number of cutting axes |

Single / Double |

Single | |||||

| Cutter holder | Exchange | One touch exchange | |||||

| Stripper pressure | By adjusting pressure reducing valve / By numerical settings on touch panel | ||||||

| Cutter heater | - / Heater temperature Max. 70℃ | ||||||

| Blade tilt adjustment | - / Blade tilt adjustment | ||||||

| Cutting table | Work fixation | Vacuum suction | |||||

| Suction hole | Grid arrangement / Porous (stepless suction) | ||||||

| Rotation angle | 90° / 270° (180° optional) | ||||||

| Heater | - / Bulit-in heater temperature Max. 130℃ | ||||||

| Work alignment | - / Alignment fingers in four directions | ||||||

| Camera | Display | - | Images displayed on 15-inch display | ||||

| View | - | 4.5 mm×2.4 mm (45° angled) |

13.9 mm×2.7 mm (15° angled) |

||||

| Image sensor | - | 720×540 (390,000 pixels, 1/2.9 CMOS) |

2048×1536 (3.2 million pixels, 1/1.8 CMOS) |

||||

| Lighting | - | LED with adjustable illumination area | |||||

| Image processing | Image processing | - | Image processing of marks on work surfaces or sides for position alignment | ||||

| Detection method | - | Binary centroid calculation / Pattern matching | |||||

| Cutter cleaner | Cleaning | - /Cutter cleaner slides in parallel to blade for cleaning the tip | |||||

| Safety devcice | Hearted cutting table | - / Overheat prevention sensor | |||||

| Cutting table, cutter | Safety cover / Safety light curtain | Safety light curtain | |||||

| Rear side | Door with safety sensor (only for double cutting axis) |

- | |||||

| Control | Control unit | UHT made controller (MOCO) | |||||

| Operation | 10 inch color touch panel | ||||||

| Network | - / LAN between machine and PC | ||||||

| Power source | 3φ AC 200V ±10%, 7 kVA (9 kVA if equipped with optional Z2 axis) |

- |

|||||

| Air source | 0.4 - 0.7 MPa (clean air) | ||||||

| Size | W790×D1220×H1670mm | - | |||||

| Weight | Approx. 1200 kg | - | |||||

| Loader | Model | Type L | Type A | ||||

| Structure | External module | Integral type | |||||

| Type | Line loader | ||||||

| Pre-alignment | - | Edge camera | |||||

| Power source | 3φ AC200V ±10%, 8 kVA (10 kVA if equipped with optional Z2 axis) |

3φ AC200V ±10%, 9 kVA |

|||||

| Size | W1580×D1220×H1670 mm | W1350×D1230×H1670 mm | |||||

| Weight | Approx. 1600kg | Approx. 1400 kg | |||||

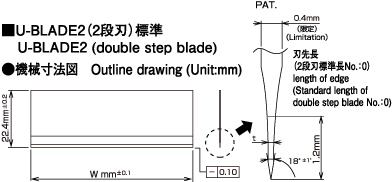

Option

High quality carbide alloyed blade for fine cutting, and long life.

Outline Drawing

Industrial processing equipment Product lineup

Support

Contact Us

- Inquiries about products

Request catalog here

- Reception time:9:00~18:00(Weekday)