Products

- HOME

- Industrial processing equipment

- Laser

- RtoR Laser Puncher

Laser

Industrial processing equipmentトップRtoR Laser Puncher

RLP series

- Films

- RLP-S220U

- Roll-to-roll laser drilling of microviasat high speed

- Small footprint and high productivity by movable processing head and automated roll transfer system

Continuously stable high-accuracy processing with our original control technologies and automatic compensation functions

Characteristics

- The original optical scanning system controller and digital galvo scanner allow high-speed and high-accuracy processing.

- Scanning area: 50×50 mm, optionally 30×30 mm or 70×70 mm

Galvo speed: 2500 PPS - Large sheet size up to 500×500 mm

- Customized table available to suit the sheet and processing pattern

- Optical system tailored to the film material and processing application

- UV lasers as standard or different types of lasers available

- Safety

- Class-1 laser product in compliance with JIS

- Simple and easy operation

- Excellent usability with the movable operation panel

Standard Specifications

| Model name | RLP-S220U | ||

|---|---|---|---|

| Processing | Material | Films | |

| Dimensions |

Roll width: max.500mm, diameter: max. φ200mm |

||

| Processing area | Max.500mm × 500mm | ||

| Processing | Hole size |

30μm |

|

| Method | Percussion or trepanning | ||

| Table | Suction table | ||

| Capability | Processing accuracy |

±15 μm (on UHT test sheet) |

|

| Galvo speed | 2500PPS (0.5mm pitch on X-axis) | ||

| Laser unit | Oscillator | LD pumped pulsed solid state laser Different types of lasers available (e.g. UV lasers, picosecond lasers) |

|

| Wave length | 355nm | ||

| Average power output | 15W at 50kHz | ||

| Cooling | External water-cooled chiller | ||

| Optical unit | Number of heads | 1 head | |

| System | Optical scanning system with digital galvo scanner | ||

| Scanning area | Max. 50×50mm | ||

| Laser focus | Electrically adjusted by software | ||

| Z-axis | Automatic focus adjustment of optical unit according to film thickness setting | ||

| Image processing | Mode | Image recognition of alignment marks on sheet surface by camera | |

| Detection | Binarized centroid detection or pattern matching | ||

| Camera | 1unit | ||

| Camera view | 1.7×1.3mm | ||

| Lighting | LED ring light (standard: red, optional: white, blue, or green) |

||

| Control system | Controller | UHT-made dedicated controller | |

| Operation | Color graphic LCD screen | ||

| Programs | Created on manager software installed on PC | ||

| Data storage | Max. 200,000 positions per file | ||

| Network | Processing data transmission from PC to machine via LAN PC can monitor a single machine |

||

| External dust collector | Dust collection from above sheet | ||

| Dust control measures | Air purge system for optical units, protection glass for f-theta lens, axis covers |

||

| Safety measures | Safety covers, key switches, safety interlocks | ||

| Laser indicator |

Green: laser ready (shutter open), |

||

| Laser class | JIS Class 1 laser product | ||

| Power supply |

2 systems; Machine: 3-phase, 200V AC ±10%, 10kVA |

||

| Air supply | 0.4 - 0.7MPa (clean air) | ||

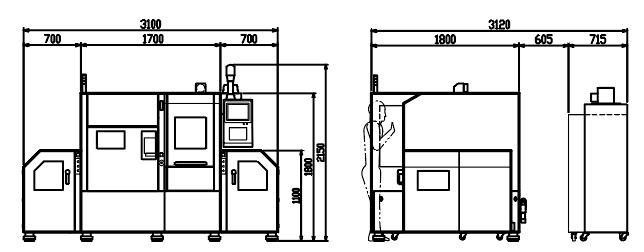

| Machine | Dimensions | W3100×D1800×H1800mm | |

| Weight | Approx. 4000kg | ||

| Environment | Temperature | 10 - 35℃ (22 ±2℃ recommended) | |

| Humidity | 40 - 60% (non-condensing) | ||

| Vibration | No shock or vibration | ||

Options

- Mask

nominal dia: 1.4 - 4.0 mm, 0.1 mm increments, sizes to be specified(Square masks available) - Alignment & suction table

- Laser energy measurement function

- *Power box

- *CAD conversion software

- *Control PC & Processing data creation software

*Items with an asterisk are required for the first machine.

Outline Drawing

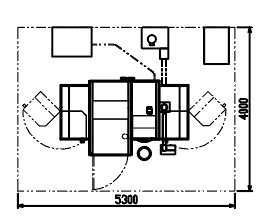

Example of floor layout

Industrial processing equipment Product lineup

Support

Contact Us

- Inquiries about products

Request catalog here

- Reception time:9:00~18:00(Weekday)