Products

- HOME

- Industrial processing equipment

- Peripherals

- Ceramics Casting System Machine

Peripherals

Industrial processing equipmentトップCeramics Casting System Machine

CCS-710 series

- New casting system by integrating the process from coating to drying in a compacted manner

- A flexible condition setting can be set with touch panel.

- Coating thickness: 5 to 200μm Coating width: Max.250mm Drying temperature: Max.150℃ Speed: 200 to 12,000mm/min.

- Easy setting

Characteristics

- Flexible condition setting

-

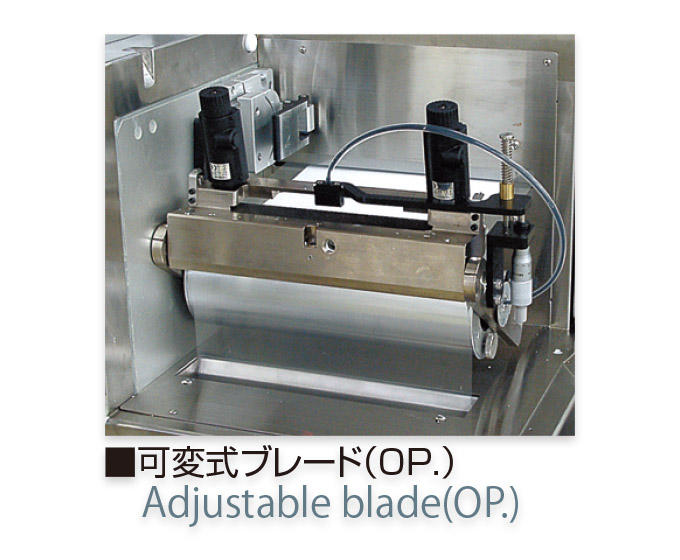

- Adjustable and fixed type casting head blades are prepared.(OP.)

- Adjustable type casting head blade can flexibly set coating thickness. You can easily exchange the installation of adjustable and fixed type casting head blades.

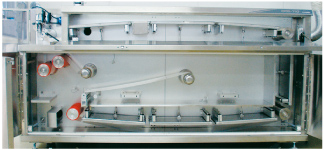

- The condition during coating can be set.

- Coating conditions (temperature, amount of blow, feed speed and tension) can be set at one location.

- Minute control of drying condition

- The amount of ventilation and the temperature of seven table heaters can be individually controlled.

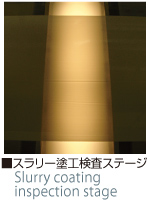

- Inspection of slurry coating

- Backlight stage allows easy check the state of coated condition of slurry.

- Easy cleaning and film exchange

- Easy structure of cleaning and film exchange

- Safety

- Safety structure to separate coating section and the control board

Standard Specifications

| Model | CCS-710 | |

|---|---|---|

| Coating | Method | Doctor blade method used for coating on the film(Adjustable-type: option / Fixed-type: option) |

| Material | Ceramics slurry | |

| Width size | Max.250mm(Width of career tape:260mm) | |

| Thickness | 5~200μm(Depend on the slurry codition) | |

| Speed | 200~12,000mm/min | |

| Inspection | Backlight used for visual inspection of coating condition | |

| Supply of slurry | Tube pump used to supply slurry to the liquid dam.(Option) | |

| Film(roll) | Outer diameter of unwinder | Max. 220mm in diameter |

| Outer diameter of winder | Max. 300mm in diameter | |

| Weight | 25kg or less | |

| Installation shaft | φ3B(3B paper tube clamping) | |

| Dryness | Method | Table heater used to dry slurry from below the carrier tape |

| Temperature | Max.150℃ | |

| Zone/Length | 7 zone×500mm=3,500mm | |

| Air blow | Two fans used to control the suction/exhaust amount to select optimal drying conditions (Air blow control up to 60℃ is possible for option.) | |

| Carrier film | Film feed | Winding with the servo motor. Powder blake used to control tension for unwinding. |

| Meandering prevention | Unique mechanism adopted to prevent the tape from meandering. | |

| Cleaning | Adhesive roll used to clean both sides of the tape before coating. | |

| Control function | Control unit | Dedicated controller for mechanical control made by UHT (MJUC) |

| Operation | Operation with the 10.4-inch graphical touch panel | |

| Static eliminating unit | The static eliminating bars are set up with 1 piece for each unwinding and winding side. | |

| Safety | Cover | Heat-insulated, sealed type |

| Structure | The operation panel is separated from the coating section and air purge is conducted for the equipment box to prevent solution gas from entering. | |

| Material and structure of housing | Stainless steel welded frame | |

| Air pressure source(for static eliminating) | Pressure | 0.2~0.5MPa(Clean air) |

| Connected diameter | Outer diameter φ12 tube | |

| Exhaust | Flowing quantity | Max 8.1m3/min |

| Duct connected diameter | Outer diameter φ73mm | |

| Power sourse | 3φ AC200V ±10% 5kVA | |

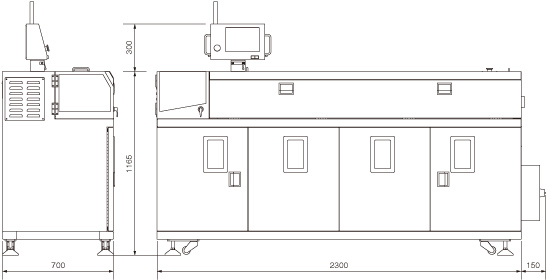

| Dimension | W2300(Breaker box+150mm)×D700×H1165mm(Operation panel+300mm) | |

| Weight | Approx.700kg | |

| Working condition | Temperature | 10~35℃(22±2℃ recommended) |

| Humidity | 40~60%(Non-dewing) | |

Options

- Casting head, blade

- Adjustment jig for adjustable casting head

- Pump that automatically supplies slurry

- Temperature adjustment heater for slurry

- Articles of consumption

Outline Drawing

Industrial processing equipment Product lineup

Support

Contact Us

- Inquiries about products

Request catalog here

- Reception time:9:00~18:00(Weekday)