Products

- HOME

- Industrial processing equipment

- Punching

- Roll Type Film Material Punching Machine:3-axis Unit Type

Punching

Industrial processing equipmentトップRoll Type Film Material Punching Machine:3-axis Unit Type

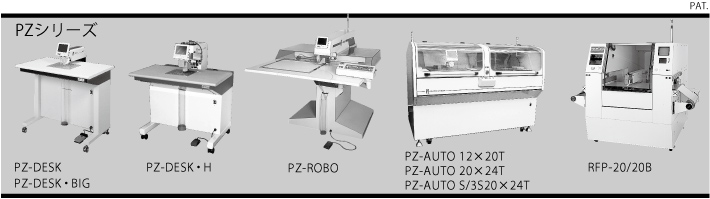

RFP-3P20 series

- Applicable to several materials. Fits for 500 mm roll width of metal foil, resin film and paper, etc.

- Various processing is realized. System to exchange loading units realizes circle punch, pattern and outside blanking, etc.

- For quality control. Installing of the testing system.

Characteristics

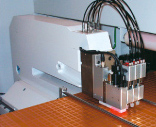

- System to exchange loading units

- Installing by choosing from punching die units: PU-25 PU-50 PU-25 (OP.)

- Installing of the testing system can control quality.

- Testing punched holes and measuring accuracy punching the center of target marks.

- Can create punch data by teaching method.

- Can input numerical value into PC, and can easily create data by monitoring and teaching patterns with camera.

- Work tension mechanism and roll edge control enable high accuracy processing.

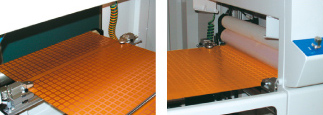

- Photos: 4-position clamper and built-in cleaning roller (OP.)

- High rigidity punching frame enables high accuracy processing.

- Light weight and high rigidity frame with ductile iron casting box type frame enables high accuracy processing.

- Space saving compact design

Standard Specifications

| Model name | RFP-3P20 | |

|---|---|---|

| Work | Material | Metal foil, Resin film, Paper, etc. |

| Size | Max.500mm(Roll width) Max.φ400mm Thickness:10~200μm(Estimate・depending on a material & a hole diameter) |

|

| Max working area | Max. X500× Y:500mm | |

| Productivity | Punched hole diameter | φ0.1~6.0mm |

| Punching Accuracy | ±20μ(with image processing mode) | |

| Punching Speed | Max. 500punches/min (NC punch with 1mm pitch) Max.60punches/min (Image processing with 20mm pitch in Y direction) |

|

| Punching power | 300N(PU-25) 1000N(PU-50) With 0.6MPa | |

| Machinery | Punching unit | Offset system into CCD camera unit |

| PU-25:Three axes PU-50 PU-75(OP.) | ||

| Work clamping unit | Back tension held by nip roll and 4-position clamper | |

| R/R unit | Tension control driven by torque motor | |

| Control Function | Control unit | UHT make controller exclusively for mechanism control (MJUC) |

| Operation | Operated by 6.5 inch touch panel | |

| Image processing method | Target Mark Size | φ0.6~3.0mm |

| Searching Mechanism | Gray scale or detecting and correcting binary center of gravity | |

| Range of View | Standard View 5×4mm With image processing4.5×3.5mm | |

| Illumination | Permeation・Reflection | |

| Data | Programming method | ・Teaching play back method ・Data conversion software from CAD data direct to punching data. |

| Programming capacity | Max. 30000 Position | |

| Testing system | Testing punched holes ・Accuracy measurement ・Judgement ・PC control | |

| Power Source | 3φ AC200V±10% 1.5kVA | |

| Air Preesure Source | 0.4~0.7MPa | |

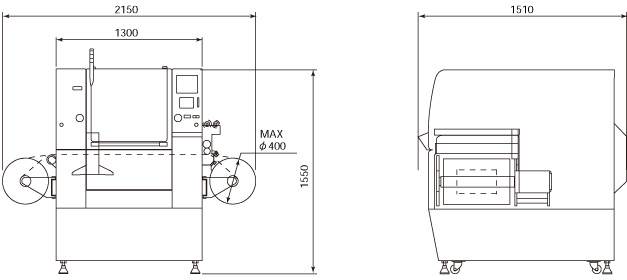

| Machine Size | W1300×D1510×H1550mm(Body) | |

| Machine Weight | Approx.1300kg | |

| Working condition | Temperature | 10~35℃(22±2℃ recommended) |

| Humidity | 40~60%(Non-crystal) | |

| Regular accessories | Punch/die/stripper 1 set Freezing air drier (Outer installation) |

|

Options

- Punching units : PU-50,PU-75

- Power box

- Air intensifier

- Lift car (Roll removing)

- NG marking unit during inspection

- Punch/die/stripper

- Cleaning roller

- CAD converting software

Outline Drawing

Industrial processing equipment Product lineup

Support

Contact Us

- Inquiries about products

Request catalog here

- Reception time:9:00~18:00(Weekday)