Products

- HOME

- Industrial processing equipment

- Laser

- 2Head 2Stage Laser Puncher

Laser

Industrial processing equipmentトップ2Head 2Stage Laser Puncher

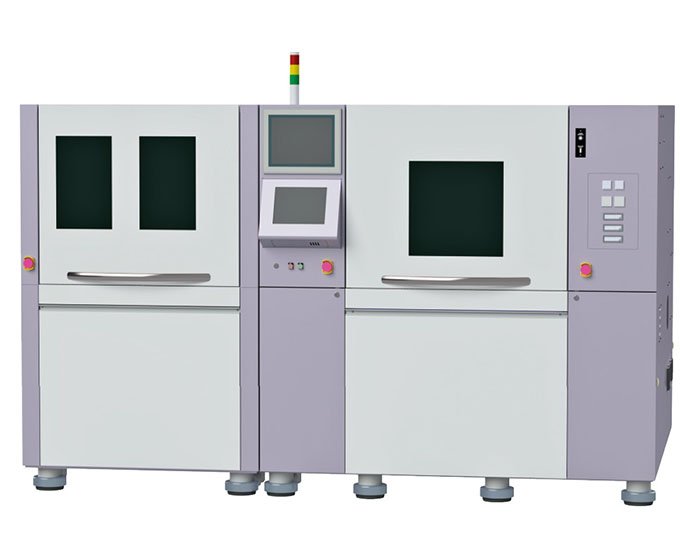

LPU series

- Green sheets, materials for ceramic substrates and green sheet laminates

- LPU-2S208DpJ / LPU-2S208DpK

- LPU-2S108DpJ / LPU-2S108DpK

- High rigid structure and compensation technology to achieve stable and high-accuracy processing

- 5000PPS (galvo speed 2500PPS×2)in double head & double stage processing

- Ultra-compact, automated all-in-one design

- Flexible automation modules optionally available on request

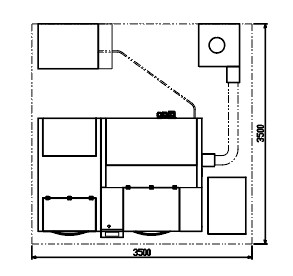

- Small footprint of 4.7 m2 (ST-DT equipped)

- Different laser oscillator types optionally available depending on work material and application

Characteristics

- The original double-head optical scanning system controller and digital galvo scanner allow high-speed and high-accuracy processing.

- Scanning area : □50mm×2heads (LPU-2S208) □30mm×2heads (LPU-2S108)

Max. processing area in conjunction with XY stage : □220 mm×2 - Series lineup

- Microvias down to 50 μm in diameter available on type LPU-2S108

Single head, single stage version for large-size materials (400×400 in size) optionally available - Compact, automated all-in-one design for easy installation

- Small footprint of 4.7 m2 (W 2600×D 1800mm) when ST-DT equipped

- High-stability and high-power CO2 laser

- Low running cost by adopting a sealed-o laser with long gas exchange intervals

- Safety

- Class-1 laser product in compliance with JIS

- Optional automation modules available

- Cleaner unit optionally available

Customized suction table to suit the processing pattern

Standard Specifications

| Model | LPU-2S208DpJ | LPU-2S208DpK | LPU-2S108DpJ | LPU-2S108DpK | |

|---|---|---|---|---|---|

| Work | Material | Ceramic green sheets with or without PET films | |||

| Punching area | Max. 220×220mm, rectangles available | ||||

| Punching area Size, Thickness | Max. 230×230mm, rectangles available; Max. 0.5mm | ||||

| Processing | Hole size | φ70~200μm | φ50~150μm | ||

| Mask change type (dependent on material, thickness, parameters) | |||||

| Method | Mask imaging (Max. 12 masks can be set.) | ||||

| Table | 2 suction tables | ||||

| Capability | Punching accuracy | ±10 μm (on UHT test sheet) | |||

| Galvo processing speed | 2500PPS×2 heads (0.5mm pitch on X-axis) | ||||

| Laser unit | Oscillator | RF excitation CO2 laser Different types of lasers available (e.g. UV lasers, picosecond lasers) |

|||

| Wave length | 10.6μm | 9.4μm | 10.6μm | 9.4μm | |

| Average output | 450W | 400W | 450W | 400W | |

| Cooling method | External water-cooled chiller | ||||

| Optical unit | Number of processing heads | 2 head | |||

| Method | Optical scanning system with digital galvo scanner | ||||

| Scanning area | Max.□50mm | Max.□30mm | |||

| Laser focus adjustment | Electrically adjusted by software | ||||

| Z axis | Method |

Automatic focus adjustment of optical unit according to sheet thickness |

|||

| Image processing | Method | Image recognition of alignment marks on sheet surface by camera | |||

| Detection method | Binarized centroid detection or pattern matching | ||||

| Image processing camera | 1 unit×2 heads | ||||

| Camera view | 3.5×2.6mm | ||||

| Lighting | LED ring light (standard: red, optional: white, blue, or green) | ||||

| Control | Control unit | UHT-made dedicated controller | |||

| Operation | Color graphic LCD screen | ||||

| Data editing | Created on manager software installed on PC | ||||

| Data memory capacity | Max. 200,000 positions per file | ||||

| Network |

Processing data transmission from PC to machine via LAN PC can monitor a single machine |

||||

| Machine cooling | External chiller to cool the machine and optical system | ||||

| External dust collector | Dust collection from above/below sheet and inside the machine | ||||

| Dust control measures | Air purge system for optical units, protection glass for f-theta lens, axis covers | ||||

| Safety measures | Safety covers, key switches, safety interlocks | ||||

| Laser indicator | Green: laser ready (shutter open), red: laser emission in progress | ||||

| Laser class | JIS Class 1 laser product | ||||

| Power source |

2 systems; Machine: 3-phase, 200V AC ±10%, 22kVA |

||||

| Air source | 0.4~0.7MPa(Clean air) | ||||

| Automation module | Stacking loader "ST-DT" | ||||

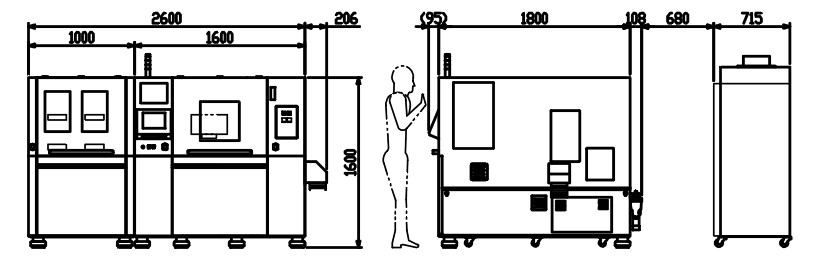

| Machine | Dimensions | W2600×D1800×H1600mm | |||

| Weight | Approx. 4400kg | ||||

| Environment | Temperature | 10~35℃(22±2℃ recommended) | |||

| Humidity | 40 - 60% (non-condensing) | ||||

| Vibration | No shock or vibration | ||||

Options

- Mask

nominal dia: 1.4 - 4.0 mm, 0.1 mm increments, sizes to be specified(Square masks available) - Alignment & suction table

- Laser energy measurement function

- Cleaner unit

- *Power box

- *CAD conversion software

- *Control PC & Processing data creation software

*Items with an asterisk are required for the first machine.

Outline Drawing

Example of floor layout

Industrial processing equipment Product lineup

Support

Contact Us

- Inquiries about products

Request catalog here

- Reception time:9:00~18:00(Weekday)