Products

- HOME

- Industrial processing equipment

- Punching

- MULTI PUNCHING MACHINE FOR CERAMIC GREEN SHEET-Z

Punching

Industrial processing equipmentトップMULTI PUNCHING MACHINE FOR CERAMIC GREEN SHEET-Z

MP-□□□□Z series

- MP-7150Z / MP-8200Z

- High speed, high precision punching fine holes

- ・Speed: 1000 holes/min (on PU-25L unit, conventional ratio: about 1.6times) Accuracy ±10μm.

- Machines suitable for trial manufacture, variety kinds of productions in small rot or medium mass-production are developed.

- ・Processing area and punch shaft number are selectable from 6 types of machines. □ 7 shafts is selectable for 150 mm processing area. □ 8 shafts is selectable for 200 mm processing area.

・Combination of loader module and unit is multiple. - Various types of units and punching methods are available.

- ・Initial costs and running costs are reduced.

・Processing methods suitable for reference hole, micro diameter, gang, and grid are developed.

・Air electric driving type punching suitable for processing is introduced. - Graphical touch panel materializes easy operation.

- Compact design contributes to reducing space.

Characteristics

- XY robot

- Maintenance-free AC servo motor has been adopted as an actuator. The specially built finger has removed deflections during machining by firmly fixing the work holder. High precision and high feed speed of 30m per minute has been realized by one micron per pulse and simultaneous biaxial feed. Machining time can be reduced a great deal.

- Automatic peripheral equipment (O.P.)

- Built-in units and outside modules are available depending on production of roll or sheet.

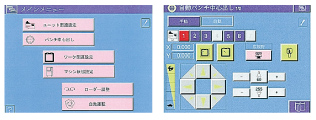

- MJUC controller

- Introduction of page type graphic touch panel enables easy operation.Control function, such as punch and die

- CCD camera unit

- Two different view cameras are installed. This unit enables simple positioning for replacing punch unit, and centering of work coordinate and correcting rotation by image processing.

- Control PC (option)

- The system can be flexible to achieve rationalization and labor-saving including the network capability with up to 14 stations by one control PC. Operation procedure will be displayed in a way easy to understand according to programs such as coordinates entry, saving/reading files and punch pattern verification by graphic display.

- Punch unit (PAT)

- Slide and clamp method is used to load the unit for easy loading, unloading and changing.

- Various units suitable to perforating quality and patters

-

- High speed, fine, perforating type

- 1axis/gang mold type

- Simultaneous perforatinggrid of a pattern

- High accurate perforation available by micro type

- Flexible unit enables multi-combination.

- Servo type with high speed punching

- High speed, fine, perforating type

Standard Specifications

| MP-7150Z | MP-8200Z | ||

|---|---|---|---|

| Workpiece | Material | Ceramics Green Sheet | |

| Work Thick | t:Max1.0mm | ||

| Punching Area | Max:□150mm | Max:□200mm | |

| Standard Work Holder | □224mm×t0.4mm | □274mm×t0.6mm | |

| Attachment(How to attach) | V/F clamp | ||

| The Number Of The Punch Units PU-25 loading shaft | 7axis | 8axis | |

| Decided by you (ref. available unit table) | |||

| Machining(Processing) | Punching Accuracy | ±10μm(2 points(R) of alignment marks (tooling punch holes) are image-processed in the standard punching range using UHT test film. Relative position accuracy while positioning and processing on the basis of a center between 2 marks.) | |

| Resolve Capacity | 1μm/1Pulse X.Y axis | ||

| Punching Speed | Max.1000 holes/min(on PU-25L),Max.600holes/min(on PU-25)(NC machining at 1mm pitch in X direction. Variation depending on process,material and condition.) | ||

| The number of the processing position memories | 1file(30000 positions) | ||

| Dust removal | Triple dust collectors with two operating methods switchable - intermittent,continuous- | ||

| Control Function | Control unit | UHT make controller exclusively for mechanism control | |

| Operathion | Graphical display by 6.5″ TFT color liquid crystal | ||

| Dedicated interactive | Software on PC (lndependent of the main body) | ||

| Network | Transmission of machining datafrom PC to the machine through LAN Centralized monitoring of the machine operating condition (up to 14 units) on PC | ||

| Power Source | 3φ.200VAC ±10% Electric power of main unit is 600VA. | ||

| Air Source | 0.4~0.7MPa | ||

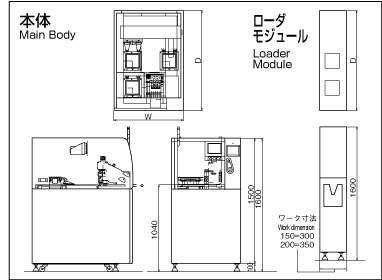

| Machine Size | W | 830mm | 955mm |

| D | 1200mm | 1280mm | |

| H | 1600mm | ||

| Machine Weight | 620kgf | 670kgf | |

| Working condition | Temperature10~35℃(22±2℃ recommended) Humidity40~60%(anti-dewing) | ||

OPTIONAL

Autoloader

module

Stack Loader,Unloader(ST-150、ST-200)

Stack Loader(ST-150L、ST-200L)

Stack Unloader(ST-150U、ST-200U)

Roll Cutting Loader(RC-150、RC-200)

unit

- Slide loader

- Elevator loader

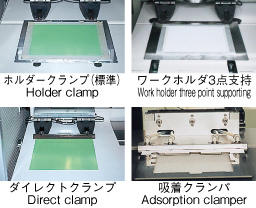

Clamp method

Work holder clamp is standard(V/F). 3 point supporting, direct clamp, and adsorption clamp are available.

θ finger

θ finger enables θ correction of work.

Area sensor

Checking is done by the area censor in front of the machining portion. When the sensor detects a part of hands or something that blocks while the machine is working, it stops the machine. It ensures high quadivty of safety, just in case.

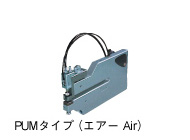

Punch unit

According to type or size of mold, air type unit or motor-driven unit, for width between 25 to 150 mm, is selectable. Low cost mold is available.

Various types of molds

For every condition, modified mold or multiple pin (gang, grid) mold are available.

Punch setter

CCD camera enables to see multi-directions by rotating and materiadivzes compact setter. Mold fitting is easy through the monitor. Kit type setter, such as square

Lift car

Heavy punch unit can be easily moved or changed by divfting it . It contributes to reducing changing time and safe work environment.

Outline Drawing

Industrial processing equipment Product lineup

Support

Contact Us

- Inquiries about products

Request catalog here

- Reception time:9:00~18:00(Weekday)