Products

- HOME

- Industrial processing equipment

- Laser

- Laser Router

Laser

Industrial processing equipmentトップLaser Router

LR-S2 12×20 series

- FPC, resin film

- UV Laser

- Cutting area: 500×300mm max.

- Compact and all-in-one design machine

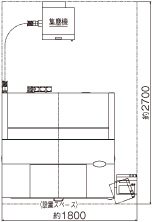

- Requires only 2.1m2 of installation space Lightening of 1800kg

- Flexible and high accuracy laser router-fine and high quality cutting on various materials

Characteristics

- Requires no guide holes for cutting in the FPC production process

- Adopts UV laser suitable for machining of FPCs and resin

- Fine and high quality cutting with a minimum heat-affected zone (burning)

- Offers various cutting shapes using UHT ′s original controller

- ●Detects changes in sheet thickness and material to choose optimal laser parameters

●Marks and skips defective substrates

●CAD conversion interface - A compact and cost-effective laser cutting machine

- User-friendly interface

- Class 1 laser safety enclosures

Standard Specifications

| Model name | LR-S2 12×20 | ||

|---|---|---|---|

| Work | Material | FPC and resin film | |

| Size | Max.W520×D320, t1.0mm | ||

| Machining area | Max.W500×D300mm | ||

| Machining | Width | 15~30μm(spot size)(Varies according to machining conditions such as workpiece material and thickness) | |

| Shape | Linear, arc, circular, spline (free curve), filling | ||

| Table | On the adsorption table | ||

| Capability | Machining accuracy | ±15μm(incl. image processing accuracy) | |

| Machining speed | Max.500mm/s(Varies according to machining conditions such as workpiece material and thickness) | ||

| Laser unit | Oscillator | Fully solid UV laser | |

| Wave length | 355nm | ||

| Average output | 10W(laser emission point) | ||

| Cooling method | Water cooling with special chiller installed outside machine | ||

| Optical unit | Method | Optical system of scanning(galvanometer type optical scanner method) | |

| Scanning area | Max.□50mm | ||

| Laser focus adjustment | Electric | ||

| Optical system of observation | Observation of the same axis as the laser beam, manual focus type | ||

| Z axis | Automatic focus adjustment of optical unit by work thickness setting | ||

| Image processing | Method | Center of gravity measurement through digitization, pattern matching | |

| Image processing camera | 2 units | ||

| Camera view | Narrow field 1.3×1.0mm, Wide field 7.4×5.5mm | ||

| Lighting | LED link light (Standard: red. OP: white, blue or green upon selection) | ||

| Control | Control unit | Special controller made by UHT | |

| Operation | Operated by 10.4 inch color liquid crystal touch panel | ||

| Data editing | By interactive software on PC (Separation from main body) ※A part of processing data can be edited even on the main body side. |

||

| Network | Transmission of machining data from PC to the machine through LAN, centralized monitoring of the machine (up to 4 units on PC) | ||

| Dust collector(set outside machine) | From the upper lower side | ||

| Dust proof measures | Air purging type in optical unit, protection glass for fθ lens, each axis cover, and dustproof protection with bellows | ||

| Safety device | Safety cover, Key switch, Safety interlock | ||

| Laser display light | 2 colors of LED | ||

| Laser class | Class-1 laser product in compliance with JIS | ||

| Power source | 3φ AC200V ±10% 3.5kVA | ||

| Air source | 0.4~0.7MPa(Clean air) | ||

| Workpiece supply | Standard: manual feed (OP. automated) | ||

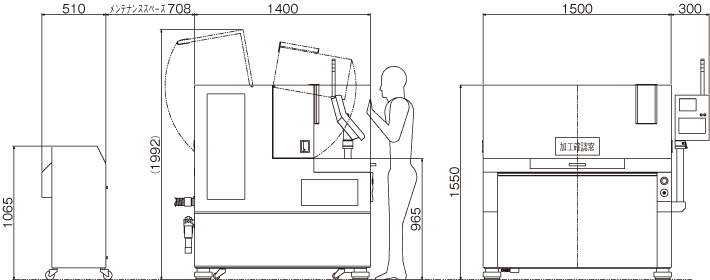

| Machine | Size | W1500mm×D1400mm×H1550mm | |

| Weight | Approx. 1800kg | ||

| Working condition | Temperature | 10~35℃(22±2℃ recommended) | |

| Humidity | 40~60%(Non-dewing) | ||

| Vibration | There must be neither impact nor a vibration. | ||

Options

- Adjustment adsorption table

- ※Power box

- Laser output measurement function

- ※Control PC+LR Manage(made by UHT)

※Items with an asterisk are needed when we deliver the first.

Outline Drawing

Example of floor layout

Industrial processing equipment Product lineup

Support

Contact Us

- Inquiries about products

Request catalog here

- Reception time:9:00~18:00(Weekday)